CNC Machined Sand Casting Tooling Services

Highly engineered hybrid solutions to casting tooling can be used to create intricate complex geometries in large proto and production castings. At Pentz Cast Solutions, we design and engineer precision ITAR-registered sand casting tooling and permanent mold tooling for low and high-volume casting production. We work directly with customers in order to engineer and build CNC machined sand casting tooling and CAD engineered part models based on your exact specifications. With our in-house CNC machine capabilities and extensive array of casting tooling mediums and materials, we can build sand casting tooling for any equipment. New casting tooling is immediately reviewed in inspection to ensure your casting tooling is of the highest quality to meet your application requirements.

Contact Us online to discuss our sand casting tooling services or Request a Quote online and one of our experts will be happy to review your project.

Our Casting Tooling Process

Developing Casting Tooling Prototype

We begin by working directly with our customer to ensure that the casting tooling prototype is designed to your exact specifications. Our Engineer then designs the casting tooling in CAD, and the casting tooling is built out. We also inspect every casting tooling for safety and functionality prior to approval. At this stage, tooling revisions, if any, are made quickly.

Article Casting Creation

After tooling revisions, we collaborate as a team to create the first article casting process plan. After a plan is established, we build first article castings and inspect first article castings by X-Ray as needed. Once again, we make any necessary tooling changes and or process plan adjustments.

Casting Tooling Production

Upon casting tooling approval, we can set foundry control in process plan. Once the casting process is accepted we begin building approved production castings. We CNC machine castings to finish and prove out machining tooling.

Casting Tooling Capabilities: Materials Used

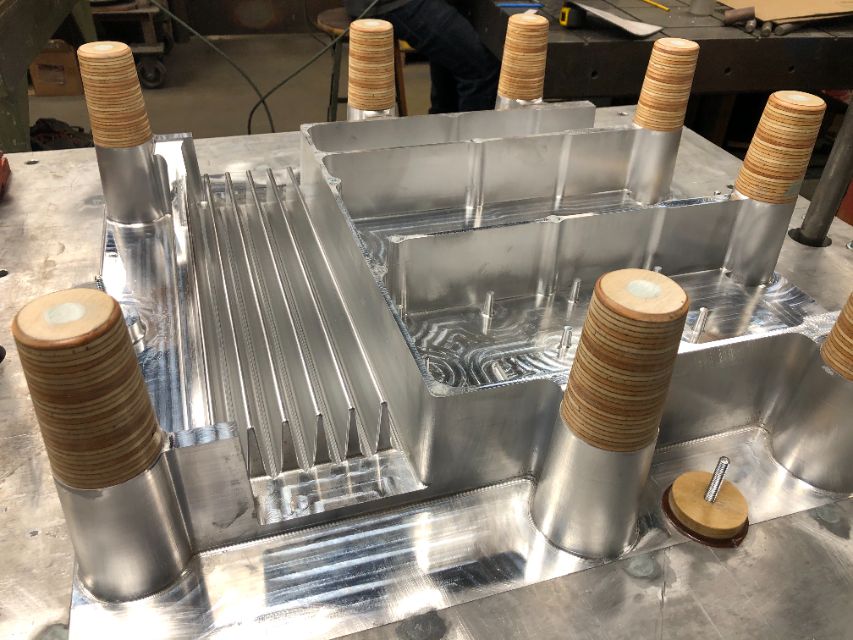

Pentz engineers and builds precision CNC machined sand casting tooling for our automated sand cast aluminum production and customer foundries by pouring gray iron, ductile iron, and bronze alloys. Casting tooling mediums include but are not limited to:

- CNC machined aluminum billet

- Plastic

- Hardwood

- Prototype Materials for quick tooling revisions.

Tooling is CNC machined in aluminum, plastic, hardwood, and iron core boxes.

Sand Casting Tooling Applications

Our in-house capabilities and casting tooling expertise enable us to create new casting tooling for virtually any application. We build sand casting tooling for any equipment, including:

- Sinto

- Disamatic

- Beardsley Piper

- Machine molding

- Floor molding

- Dry sand / Air-set mold boxes

Why Choose Pentz For Precision Casting Tooling

In-House Casting Tooling

All of our designing, engineering, CNC machined tooling and CNC machining of castings allow us to complete castings by getting them done fast, right, and more efficiently. The first article cast parts made from new casting tooling are immediately reviewed in inspection and then returned to the CNC machine shop to complete the casting machining tooling process to quickly build CNC machined castings while the foundry begins building approved production castings.

CNC Precision

We have 9 CNC machining centers for building casting tooling and castings 7 vertical 4th & 5th axis, 2 horizontals, and HAAS GR 712 is 7’ x 12’ x 24” in z travels. Our quick tooling revisions enable continuous improvements.

Advanced Capabilities

We are always considering tooling design while collaborating with customers when developing cast solutions. This allows us to build parts efficiently with lower part costs. We utilize Highly engineered hybrid solutions to casting tooling to create intricate complex geometry in large proto and or production castings is what we do every day.

Coring can be accomplished with aluminum shell core box tooling, dry sand core boxes or 3D printed sand cores depending on several factors like geometry, size and quantity.

Core boxes are built in CNC machined aluminum or iron for automated high production runs.

Casting Tooling For Multiple Industries

We have experience providing casting tooling for a variety of applications and are always eager to create unique casting tooling for low and high-volume casting production. Some frequent industries served include:

- Aerospace

- Medical / Robotics / Life Sciences

- Railroad / Positive Train Control electronic cases

- Defense / Military / Homeland Security

- Transportation / Automotive / Truck / Electric Vehicle

Contact Us For Your Next Casting Tooling Prototyping Project

Thank you for your interest in Pentz Cast Solutions’ casting services. Please Contact us online or Request a Quote and let us handle all your casting Tooling needs.

.JPG)