Core Process Selection

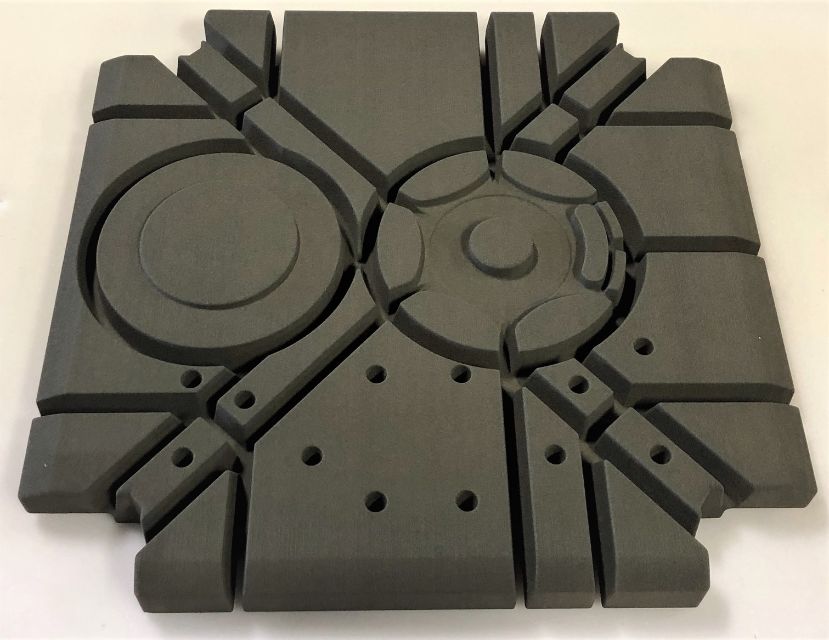

For casting complex geometries, cast-in cores provide innovative, flexible, and cost-effective solutions. Using advanced core-making techniques, coring in negative spaces and creating intricate geometries can produce high-quality cast aluminum parts for several applications across various industries. You can design and engineer challenging new products with the help of our expert engineers with custom casting cores for your applications.

Understand our unique and innovative casting core process capabilities, the materials we work with, and our job flow for creating casted prototypes and high production. Contact Pentz Cast Solutions with questions about casting core process selection or request a quote for a custom component using our core making processes.

Available Casting Core Processes

At Pentz Cast Solutions, we can produce casting cores to provide additional design flexibility for intricate and complex cast components. Prioritizing a collaborative approach, we work with you to choose a core production process that achieves your part specifications while addressing production volume requirements and preferred product finishes. Our capabilities utilize the following casting core production processes to create high-quality components for various industrial applications:

- 3D Printed Sand Core

- Automated Shell Sand Core

- Semi-Automatic Shell Sand Core

- Stock Shell Sand Cores

- Dry Sand – No Bake Core

- Dry Sand – CO2-Set Core

- Process Comparisons

Explore additional custom casting processes with proprietary resources detailing case studies for innovative solutions like cast-in stainless steel products and sand cast-in die-casting components with inserts.

Core Process Material Options

Our core production processes utilize various core making techniques and materials. Building castings with intricate coring to accomplish challenging and complex casting designs, our methods use the following materials and tooling:

- 3D Printed Core: No tooling, creates a 3D CAD model PDF

- Automated Shell Core: With custom tooling using CNC-machined aluminum or iron

- Semi-Automatic Shell Core: With custom tooling using CNC-machined aluminum or iron

- Stock Shell Core: No tooling required; available specifications of round 0.187” to 7.0” diameters

- Dry Sand – No Bake Core: With custom tooling using metal, plastic, or wood materials

- Dry Sand – CO2-set Core: With custom tooling using metal, plastic, or wood materials

Each process is suited for a variety of castings. Our knowledgeable engineers will work with you to determine the proper core and casting process to produce your desired component with high-quality results.

Job Flow for Core Making Processes

The casting core process selection is an integral part of production, helping to determine the success of a product while addressing the needs of the application and component functions. In engineering projects at Pentz Cast Solutions, we utilize our job flow chart to ensure the quality and performance of your produced parts.

Working with you, expert casting engineers decide the viability of a project before any production steps are taken. Then, the best casting process for your product is selected based on the requirements of your application. After initial steps are taken, production can begin, with consistent product testing for quality and casting and tooling adjusted as needed while also addressing feedback from clients and engineers.

Contact Pentz Cast Solutions for High-Quality Core Making Techniques

With decades of experience working with clients to deliver mission-critical components, Pentz Cast Solutions offers exceptional core making capabilities to engineer custom solutions. Our commitment to quality and innovation is demonstrated through our industrial expertise and precision products created to your exact specifications. Discover high-quality casting solutions and core making techniques from Pentz Cast; contact us with your questions or request a quote today.

.JPG)