Dry Sand Precision Molding & Cores

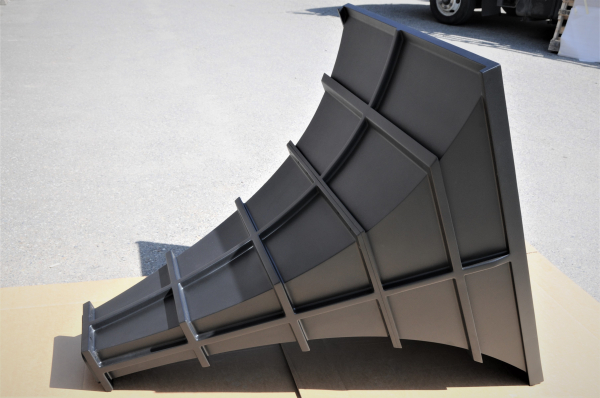

Dry Sand molding is versatile enables molds to be made in multiple directions of mold sections and cores.

We utilize the dry sand molding process to build molds, when radical geometry, like deep pockets, thin ribs or size makes it impractical to green sand mold.

Innovative engineered hybrid molding methods by combining processes of dry sand, green sand, 3D printed sections build castings with unlimited geometry and size.

Dry sand molds and cores are finished and coated to create great as cast finish.

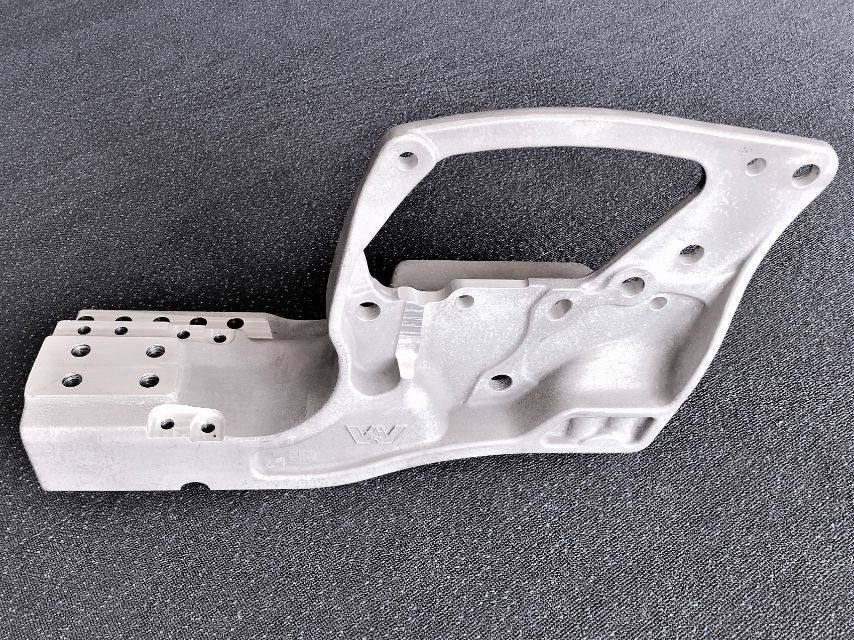

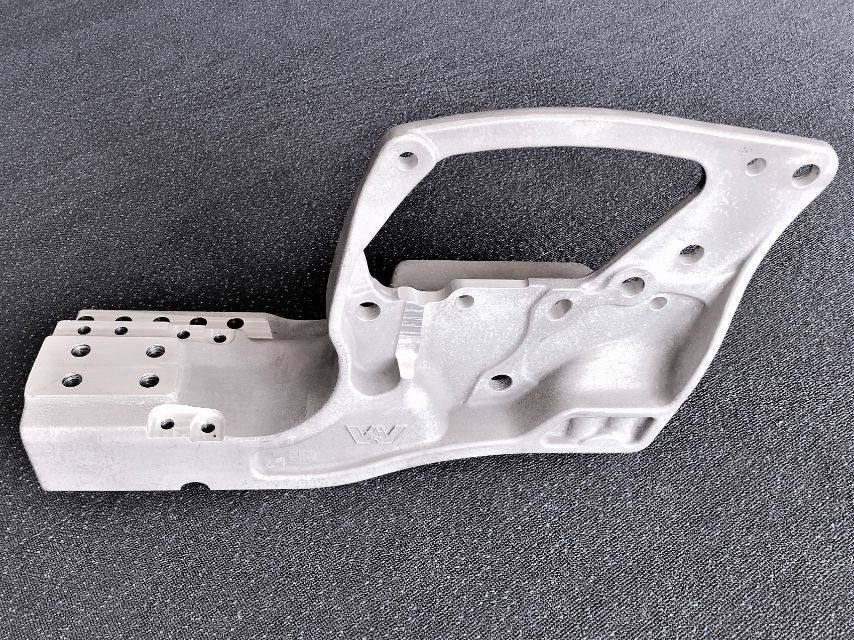

Our precision dry sand, casting tooling is typically CNC machined aluminum, plastic, wood, or a hybrid mix built with customer / Pentz approved CAD models. Tooling cost is relatively low depending on geometry and life is dependent on materials used with little tool maintenance.

Our Dry Sand Equipment List:

Tinker Omega 350 PLC controlled articulated dry sand mixer Green Diamond sand

Palmer 250 dry sand mixer Green Diamond Sand

Omco Super Bowel mixer Sodium Silicate CO2 Green Diamond Sand

Core blower or hand rammed for prototypes and low production projects.

Vibration tables compact dry sand molds for larger high production jobs.

Contact Us

Our engineers have experience creating mission-critical components for virtually any industry, and we thrive on challenging projects and love to explore innovative cast solutions in collaboration with our customers to push beyond boundaries. We can create small castings, large castings, prototypes, 3D printed molds and additional components from most machinable materials.

Contact Us and we can discuss your next project or Request for Quote on our casting services online.