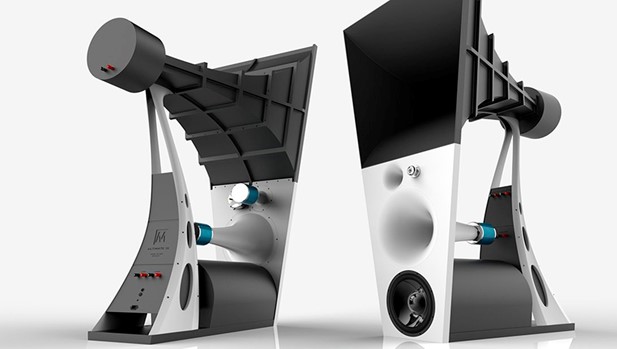

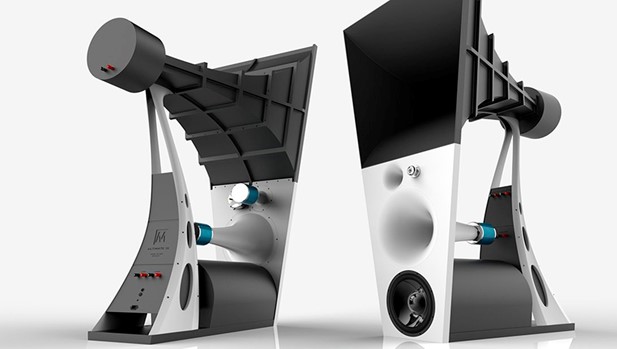

Speaker Large Casting Conversion

The Challenge:

Convert a large, complex, aluminum sheet metal & tubing weldment assembly into two large castings to improve aesthetics, audio performance, and improve cost.

The Solution:

CAD Engineer two cast parts and casting tooling. CNC machine wood tooling for patterns and core boxes. Build speaker in two parts to allow clearance to pass through doors and assemble on site. Utilize 535 aluminum alloy for high elongation, CNC machine parts and paint to complete units.

The Results:

The Casting solution created great aesthetics, quality of sound, and improved costs.

- Images:

- CNC machined wood casting tooling

- Painted Horn Complete.

- Completed entire speaker units front and rear together.

Contact Us

Our engineers have experience creating mission-critical components for virtually any industry, and we thrive on challenging projects and love to explore innovative cast solutions in collaboration with our customers to push beyond boundaries. We can create small castings, large castings, prototypes, 3D printed molds and additional components from most machinable materials.

Contact Us and we can discuss your next project or Request for Quote on our casting services online.

%20(CASE%20STUDY).JPG)