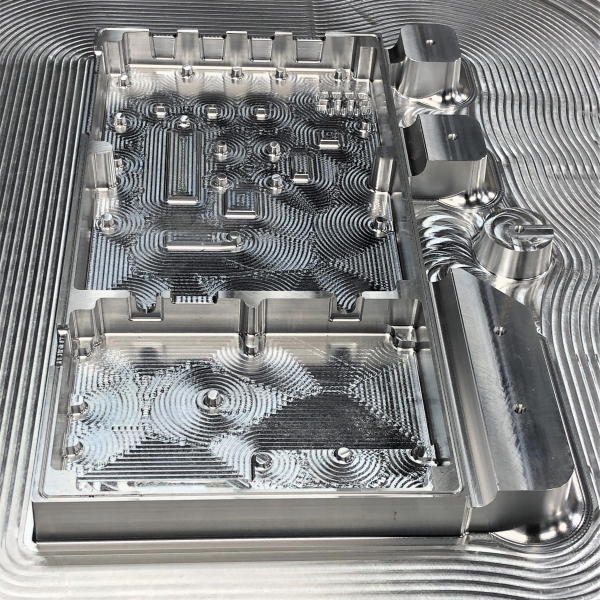

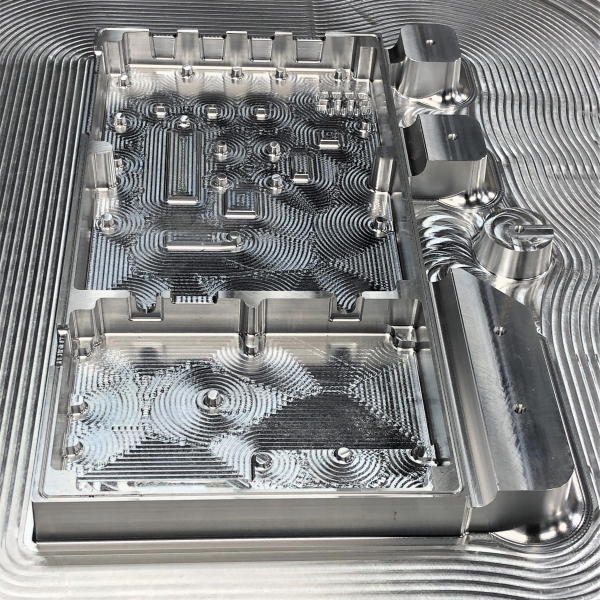

Precision Automated Sand Cast O Ring Grooves

The Challenge:

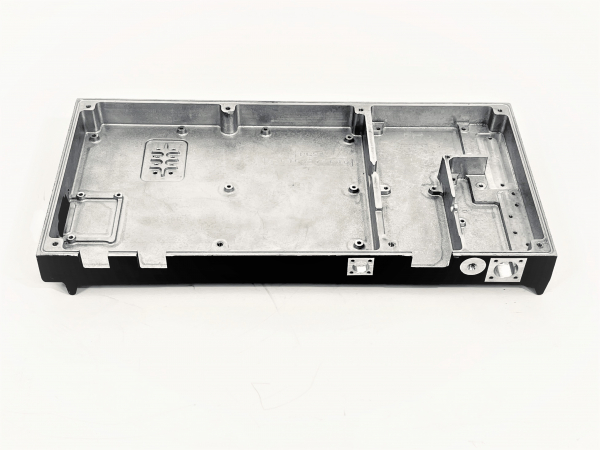

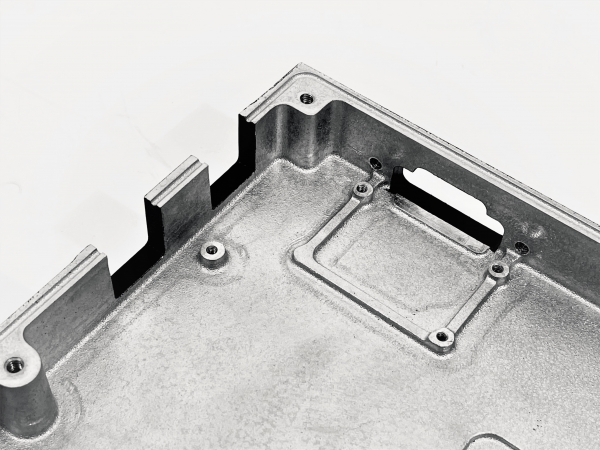

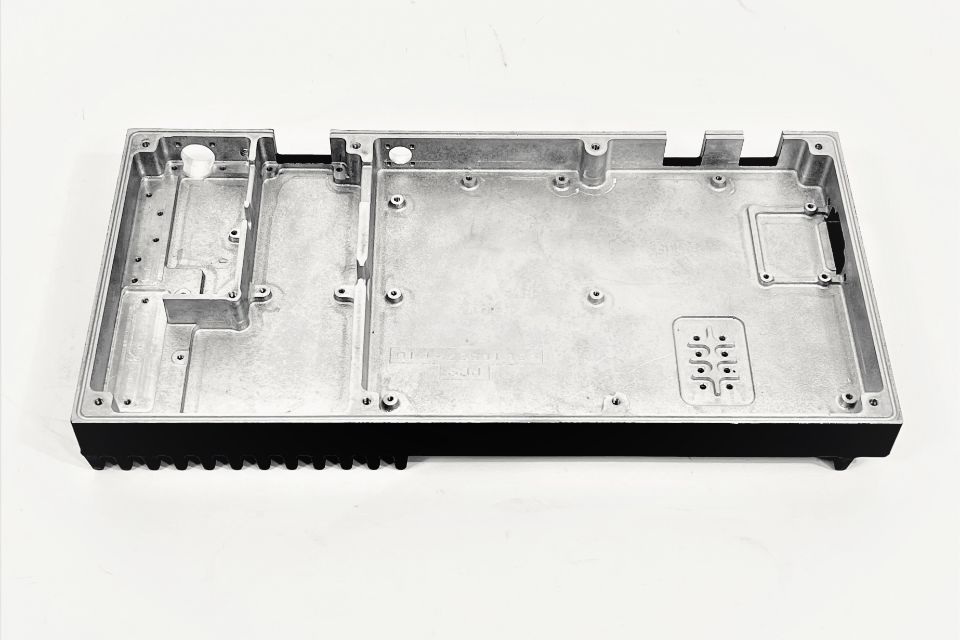

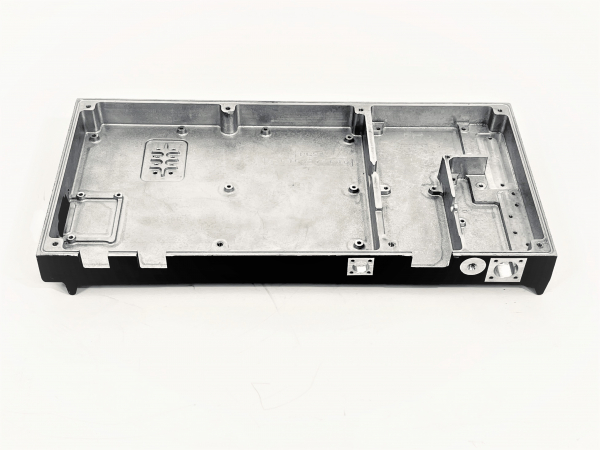

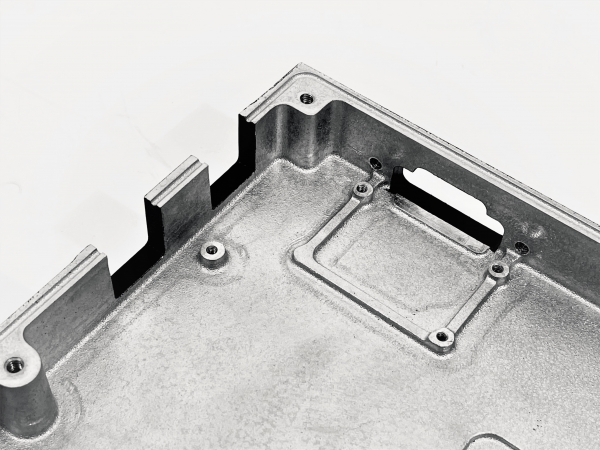

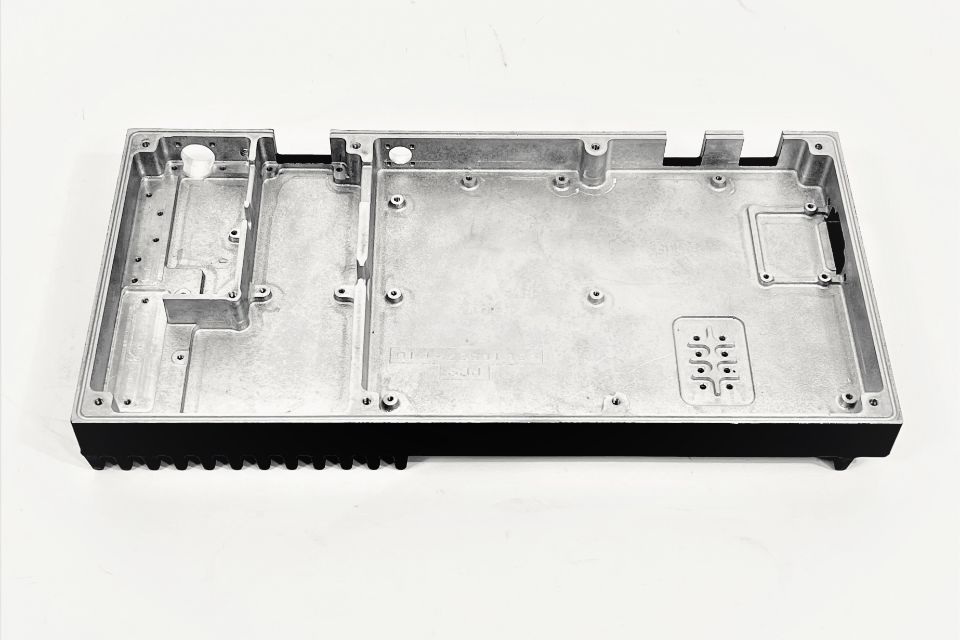

Need to build thousands of Positive Train Control cast aluminum electronics cases and CNC machine, drawing required, casting faces and small “O” ring grooves. Delivery, cost and thruput and short lead times were issues.

The Solution:

Precision automated green sand mold as cast in “O” ring grooves and faces of castings eliminating time consuming CNC machining.

The Results:

Precision automated green sand molding as cast “O” ring grooves and faces were built to machining tolerances on drawings. Accomplished dramatically improved part cost, delivery and thruput.

Contact Us

As an ITAR-Registered manufacturer of precision aluminum sand and PM castings, we take pride in creating high-performance castings designed to exceed our customers’ expectations. Our expert team of engineers and manufacturers utilize cutting-edge technology in engineering, tooling, casting, and CNC machining to take your casting from prototype thru tooling to automated casting production, CNC machining and manufacturing.

Contact Us online to discuss your next project or Request a Quote online and let our experts create castings designed to meet your application requirements.