Precision Green Sand Molding Capabilities

The term “green sand” refers to the fact that temper water is used to activate the clay in the sand to bind the sand in the mold just long enough to build a mold, pour aluminum and build a casting with superior finish. Pentz Cast Solutions has the experience and capabilities required to create sand moldings for proto and or large scale production. Our innovative sand casting equipment can turn tight tolerances and offers high repeatability to save time compared to standard manufacturing processes. Our in-house capabilities ensure each component is manufactured by a dedicated, skilled Pentz machinist and tested to Pentz Cast Solutions’ trademark “as cast” surface finish.

Learn more about our precision molding processes by reading the benefits of each molding process below or visit our molding Process Comparison chart.

Not sure where to start? Contact Us online to discuss our precision molding capabilities or Request a Quote online and one of our experts will be happy to review your project.

Precision Automated Green Sand Molding

Automated green sand molding allows for superior performance, efficiency and cost-effectiveness on custom built moldings. “As cast” .150 rms finishes can be achieved with intricate detail and complex geometries and cored interior cavities. Our precision Sinto Automated Mold System can build a precision 600, pound sand mold every 60 seconds to build your castings very efficiently.

Machine Precision Green Sand Molding

In Pentz’s machine precision green sand molding process, our skilled technicians utilize programable controls to ultimately control the system sand when forming your casting. This results in the most versatile casting process available. The sand is recirculated and reused every few hours for efficient, ecologically sound molding. Our machines include Osborn 3161 and Osborn 3191 Molding Machines.

Precision Dry Sand Molding

Dry Sand molding enables molds to be made in multiple directions of mold sections and cores. Dry sand molding is ideal for creating castings with radical geometries such as deep pockets or thing ribs. Dry sand castings often require high strength and tight sealing characteristics. Tooling cost is relatively low, and we utilize a series of innovative dry sand mixers and equipment.

Permanent Molding

We utilize the Hall 3HXS PLC controlled permanent mold system to build higher quantity, high density castings. Permanent molding is generally used for larger castings or castings with annual quantity requirements of 5,000 to or more EAU. We can build prototypes for approval prior to mass production.

Precision Molding Capabilities Comparison Chart

Not sure which molding process is right for your next project? Visit our Process Comparisons page for detailed information on all of Pentz’s green sand molding, dry sand molding, permanent molding, die casting, investment casting and hog out processes. Our comparison chart includes:

- Benefits

- Typical Part Size

- Typical Linear Tolerances

- Typical Cooling Cost

- Typical Volume & More

Quick Reference Guide

Our quick reference guide includes additional information on our selection of aluminum alloys, as well as heat treatment designators and available casting production and testing options.

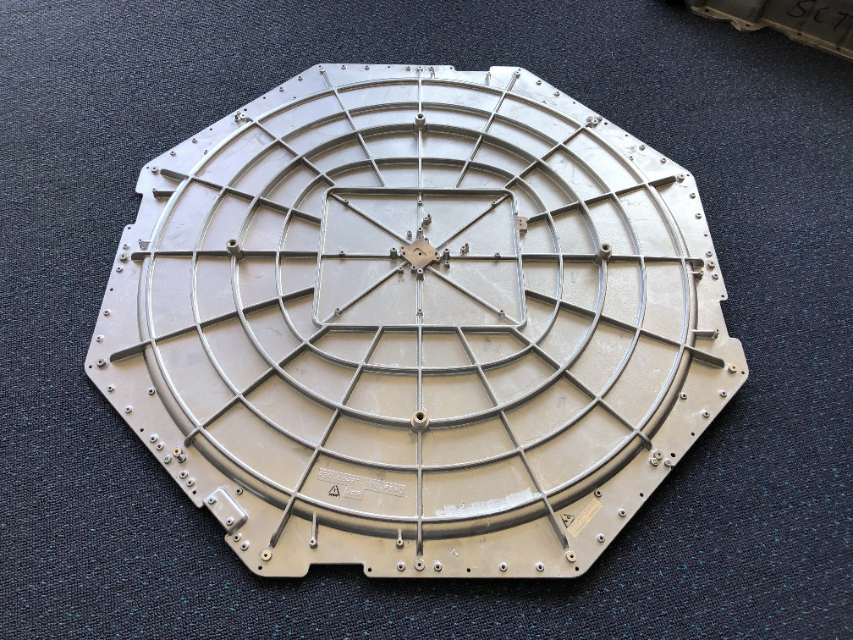

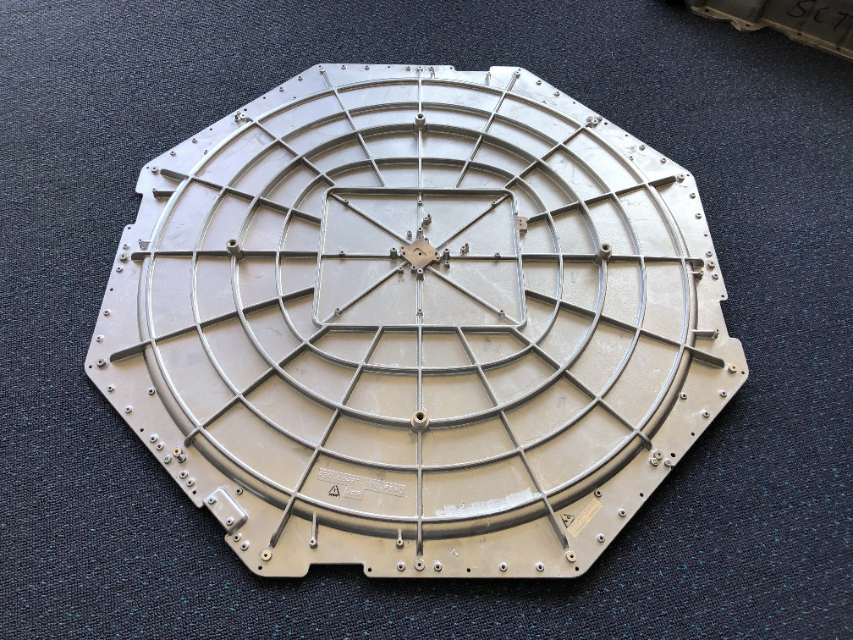

Pentz Cast Solutions’ Green Sand Molding Process

Highly skilled artisans carefully build precision green sand molds at Pentz Cast Solutions to produce the absolute best “as cast” finishes in the industry. Extraordinary smooth detailed castings with a .150 RMS finish are achieved by skilled technicians and a green sand mold system utilizing programable controls to manage system sand. Coring can be accomplished with aluminum shell core box tooling, dry sand core boxes or 3D printed sand cores depending on several factors like geometry, size and quantity. Green sand is recirculated and is used thousands of times, so it is very ecologically sound and very efficient.

We are always considering molds while collaborating with customers when developing cast solutions. This allows us to build parts efficiently with lower part costs. We utilize Highly engineered hybrid solutions to create intricate complex geometry in large proto and or production.

Precision Moldings For Multiple Industries

We have experience providing molds and components for a variety of applications and are always eager to create unique molds for low and high-volume production. Some frequent industries served include:

- Aerospace

- Medical / Robotics / Life Sciences

- Railroad / Positive Train Control electronic cases

- Defense / Military / Homeland Security

- Transportation / Automotive / Truck / Electric Vehicle

Contact Us For Your Next Molding Project

Thank you for your interest in Pentz Cast Solutions’ sand molding services. Please Contact us online or Request a Quote and let us handle all your CNC machining needs.