Quality Casting from Pentz Cast Solutions

Committed to delivering excellence and quality, Pentz Cast Solutions is a manufacturing company utilizing casting production and CNC machining, driven to meet the requirements of even the most complex applications. Custom casting and CNC machining capabilities allow for the most efficient production process to provide unique application solutions. Our quality assurance practices reflect our knowledgeable team of designers and engineers and the innovative technology used to achieve product completion.

Registrations & Certifications

Pentz Cast Solutions is dedicated to industry compliance, providing manufacturing and casting production that our customers can depend on.

To provide excellent quality, Pentz Cast Solutions is an ITAR-registered company, meeting the strict prerequisites of the International Traffic in Arms Regulations regarding the transmissions of items or technical data that have been designed, developed, adapted, or modified for military use under the United States Munitions List.

Additionally, for further quality-assured manufacturing, casting production, and products, Pentz Cast Solutions currently has ISO 9001:2015 and AS9100 certifications pending.

Quality Assurance Software & Testing Equipment

Using various quality assurance software and product testing methods, Pentz Cast Solutions aims to ensure the highest quality products are delivered. Included in our quality assurance inspection are the following capabilities:

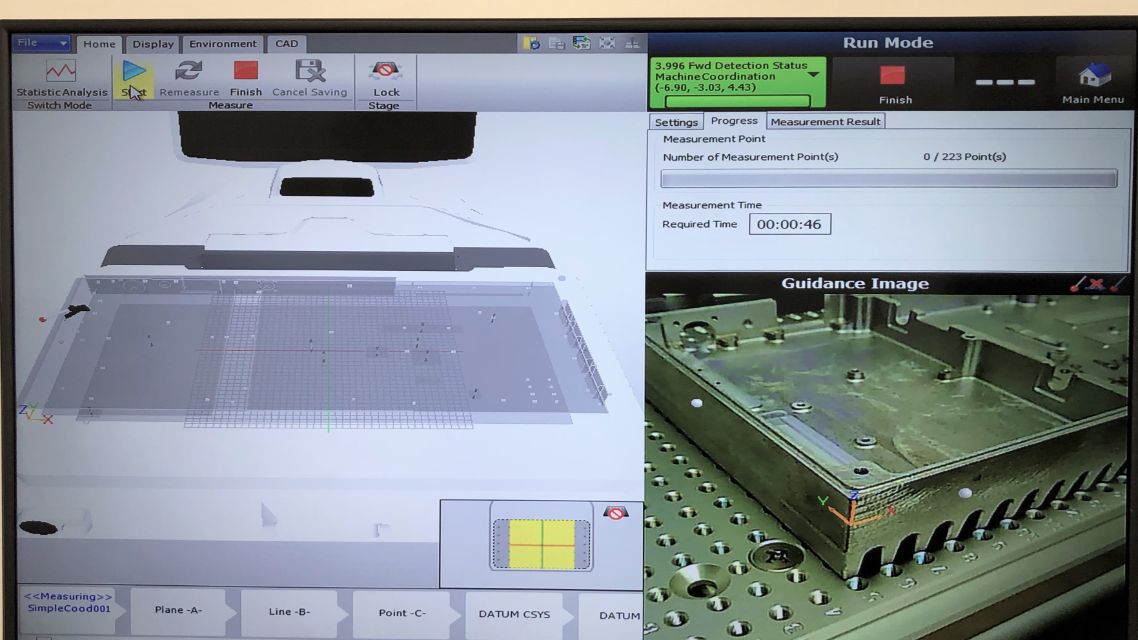

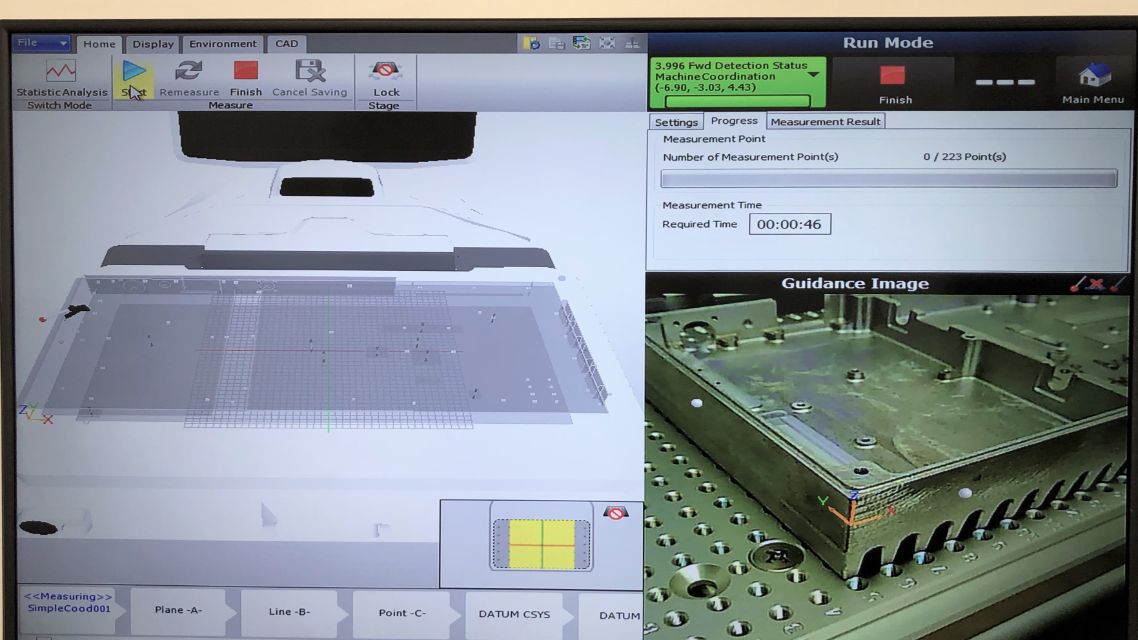

- Keyence XM Series CMM Inspection

- MRP INFOR Visual Manufacturing IQM Software

- SPECTRO/AMETEK – SPECTROMAXx Spectrometer, Arc Spark OES Chemical Analysis, Solid State

- Philips Digital “Real Time” X-Ray System, 160KV, Manipulator

- Gemini “Real Time” X-Ray System, 320 KV, Manipulator

- SPC Software

- Dye Penetrant Testing

- Ultrasound

- Borescope

- Pressure Testing

Our complete sand testing laboratory provides further quality testing, ensuring that our casting production is optimal. The sand testing laboratory quality assurance practices include:

- Dietert Lab Equipment

- Dietert #405 Sand Strength Tester

- Dietert #401 Sand Strength Tester

- Dietert Density Tester

- Dietert 276 Moisture Teller

- Permeability Meter, Electric

- Methylene Blue, Active Clay Tester

- Ultrasound Cleaner, Sample Preparation

- Electronic Lab Scale, 500 gram, +/- 1/100 gram

- Speedy Moisture Teller

- Rotap Screen Sieve Tester

Pentz Cast Solutions provides reliability and durability. Our quality assurance process also includes PPAP capabilities to inspect parts before, during, and after a production run, verifying accuracy and security in our product manufacturing process.

For additional information on AMS and MIL specifications, please get in touch with us. We’ll be happy to assist.

Pentz Cast Solutions Quality Assurance for Custom Casting Production & CNC Manufacturing

Our expert team of engineers and manufacturers utilize cutting-edge technology in engineering, tooling, casting, and CNCN machining to take your casting from prototype through tooling to automated casting production, CNC machining, and manufacturing. As an ITAR-registered manufacturer of precision aluminum sand and PM castings, we take pride in creating high-performance castings designed to exceed expectations. Contact us to discuss solutions for your next project or request a quote online and let our experts fabricate castings designed to meet your application requirements.