Casting Development Solutions

Prototype manufacturing using a mold or cast must go through casting development before production. Referring to a series of manufacturing techniques, developing a casting creates a mold for hot metal to be poured into, producing a metal component after cooling. With the ability to perform multiple steps of the casting development process simultaneously, Pentz Cast Solutions can fabricate castings faster than competitors.

Product Prototype Casting Development Process

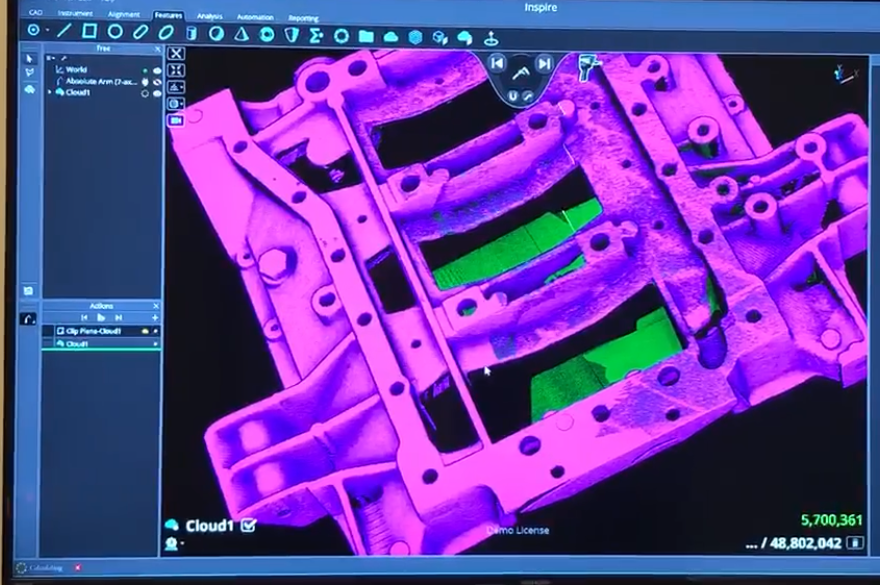

The process of developing high-quality castings begins with determining the needs of the project. Identifying specific design goals and product expectations ensures that casting satisfies the requirements before starting production. The design moves into CAD development after defining the project requirements for casting capabilities and determining an approved engineering design. Once CAD casting is complete, the next steps are as follows:

- Create a prototype

- Cast sample components

- Explore tooling process adjustments if needed

- Address quantity requirements

- Select a molding process

- Value-added services

- Quality assurance and control practices

We strive to provide high-quality castings that exceed customer and industry expectations. Using state-of-the-art equipment and certified processes, Pentz Cast Solutions casting services can manufacture the components you need to your specifications.

Advantages of Casting for Prototype Manufacturing

When selecting a prototype manufacturing process, opting for casting provides production benefits. Rapid prototyping using casting manufacturing creates a realistic product prototype before beginning a full-scale production run. Testing a reliable product design before scaled manufacturing reduces the need to modify the product mid-cycle, leading to a more cost-effective, increased manufacturing rate. Other production benefits of casting include the following:

- Uses CAD data for easy design changes

- Ability to compare alternative design concepts

- Reduces waste throughout operations

- Test product reliability before production

Types of Casting Development

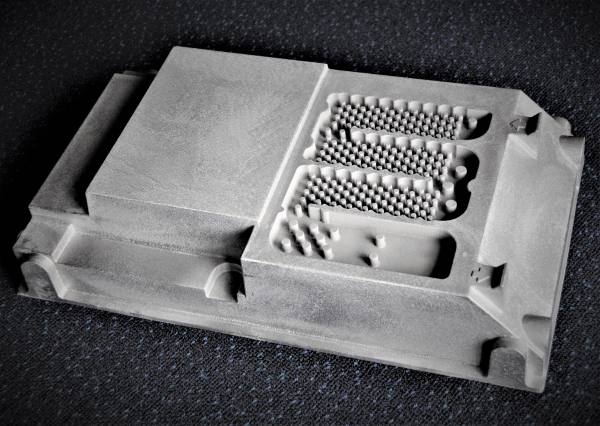

Pentz Cast Solutions offers a variety of casting development processes. We can provide automated and manual green sand molding, offering high-precision moldings to stringent and challenging requirements. Our capabilities also include permanent mold casting, providing pressure-tight moldings with lifetime use and excellent structural characteristics. Additionally, die casting offers an ideal manufacturing solution for casting non-structural components, and our investment casting capabilities can create intricate products that require high dimensional stability. Pentz Cast also offers “hog out” casting, which typically makes a one-off product prototype that does not look or perform like an actual casting. Our high-quality casting development processes and technical expertise offer unparalleled product performance.

Industries Served

Our casting development processes manufacture components for several industries. We can fabricate parts for the following industries and more:

- Aerospace

- Medical / Robotics / Life Sciences

- Defense / Military / Homeland Security

- Marine

- Food Production

- Antenna / Networking / Communication

- Oil / Gas / Refineries / Wind Energy

- Architectural Signage

- Sculpture Art

- Electrical / Electronic / Enclosures

- Medical Devices

Contact Us to Create Your High-Quality Casting Today

At Pentz Cast Solutions, our engineering experts have experience developing precision and high-performance components with complex requirements for mission-critical applications. As a trusted leader of casting innovation solutions since 1972, we are confident we can fabricate what you need. Contact us today with questions about our capabilities or development process or request a quote.