Prototype Process Selection Quality

Pentz expert engineers will collaborate with you to identify the best prototype approach for your casting to move through all phases of casting development, casting prototyping, CNC machining and through manufacturing efficiently.

Prototyping a casting creates many opportunities including:

- Create opportunities for product improvement quickly and efficiently

- Full exploration of design options quickly with minimal risks to cost and schedule

- Building “real castings real fast” enhancing sales and marketing of new products

- Provides actual castings for full testing, delivery of actual product, immediate use

- We can build protype tooling to build prototype castings

- Proves out design, tooling and manufacturing processes effectively efficiently

- Accelerates the “time to market” of new product

- Building “real castings real fast” gets it into your hands quickly!

- SLA, LOM, FDM, CNC machined 3D printed Molds & Cores, REAL cast prototypes

- Process Comparison link to Resources & Engineering

- Reverse engineering, Metrology Scan, CT Scan Link

- Prototype Process Comparison chart

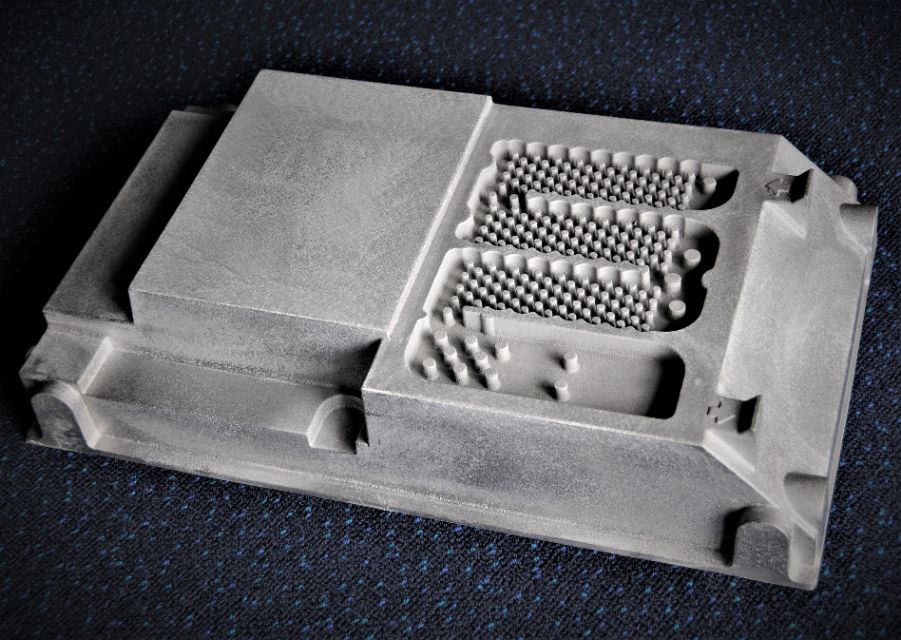

3D Printed sand molds

We use customer designed CAD files or reverse engineer castings with digital scanning processes to create CAD data. Our engineering experts collaborate closely with customers to make casting adjustments to improve casting engineering design. We add the casting shrink, machine stock and rigging to build great castings to fit customer needs fast. This allows customers to concentrate on product development as Pentz takes care of the casting side of things. Pentz TEAM is there to aid customers in all phases from concept to product realization in effective efficient aluminum castings be it prototype, short run or high production automated molded products. Pentz helps customers bridge the gap between proto processes and production needs as requirements develop over time.

Pentz utilizes methods of building rapid tooling / patterns for prototype tooling to build prototypes SLA, FDM, CNC, Plastic, Wood ect

Contact Us

As an ITAR-Registered manufacturer of precision aluminum sand and PM castings, we take pride in creating high-performance castings designed to exceed our customers’ expectations. Our expert team of engineers and manufacturers utilize cutting-edge technology in engineering, tooling, casting, and CNC machining to take your casting from prototype thru tooling to automated casting production, CNC machining and manufacturing.

Contact Us online to discuss your next project or Request a Quote online and let our experts create castings designed to meet your application requirements.