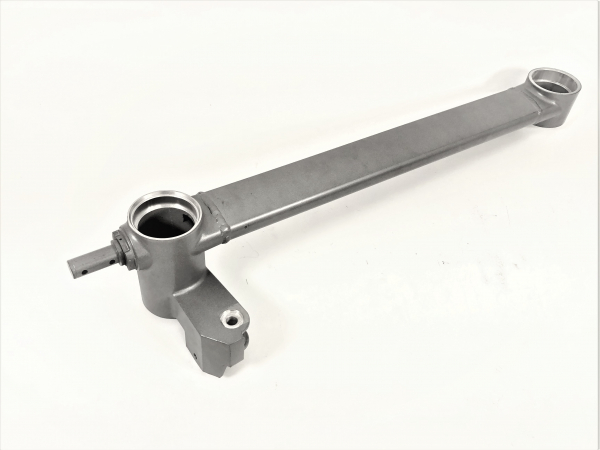

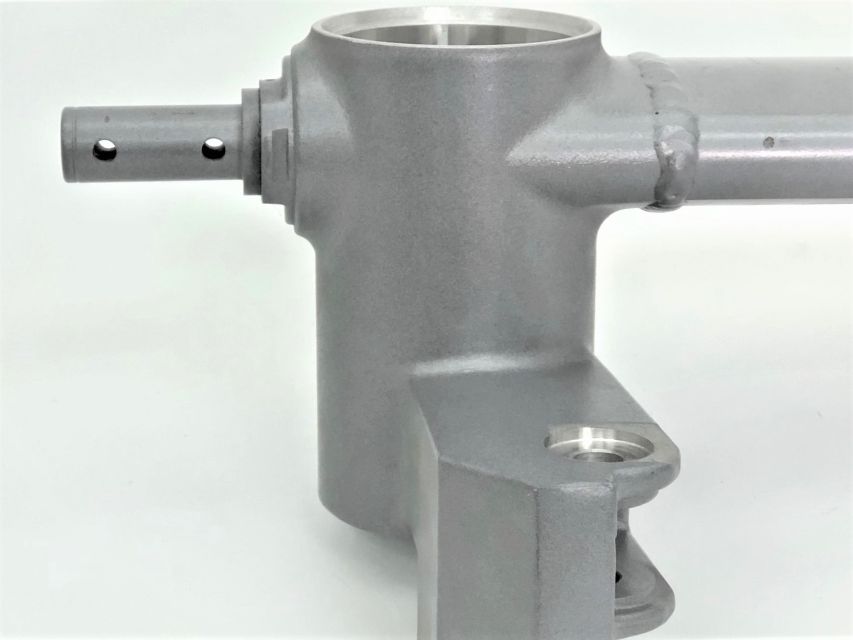

Precor Exercise Machine

Cast in steel inserts, reengineer and build new tooling fast for Precor

The Challenges:

Rapidly reengineer customer, existing product, experiencing structural issues, built by another vendor, to drastically improve casting strength. Add new cast in a CNC machined steel insert. Build production tooling and production parts fast.

The Solutions:

Rapidly reengineered new parts in CAD, with steel inserts, CNC machined new tooling. Utilizing Automated sand molding system and autometed shell core making provided high production parts quickly fulfilling customer need for reliable high strength castings. Then build permanent mold tooling and build mass quantities of castings.

The Results:

The customer quickly resumed manufacturing and shipping high volume products with zero problems. Automated production and cast in steel inserts were successful.

Contact Us

As an ITAR-Registered manufacturer of precision aluminum sand and PM castings, we take pride in creating high-performance castings designed to exceed our customers’ expectations. Our expert team of engineers and manufacturers utilize cutting-edge technology in engineering, tooling, casting, and CNC machining to take your casting from prototype thru tooling to automated casting production, CNC machining and manufacturing.

Contact Us online to discuss your next project or Request a Quote online and let our experts create castings designed to meet your application requirements.