Designing in Cast Aluminum

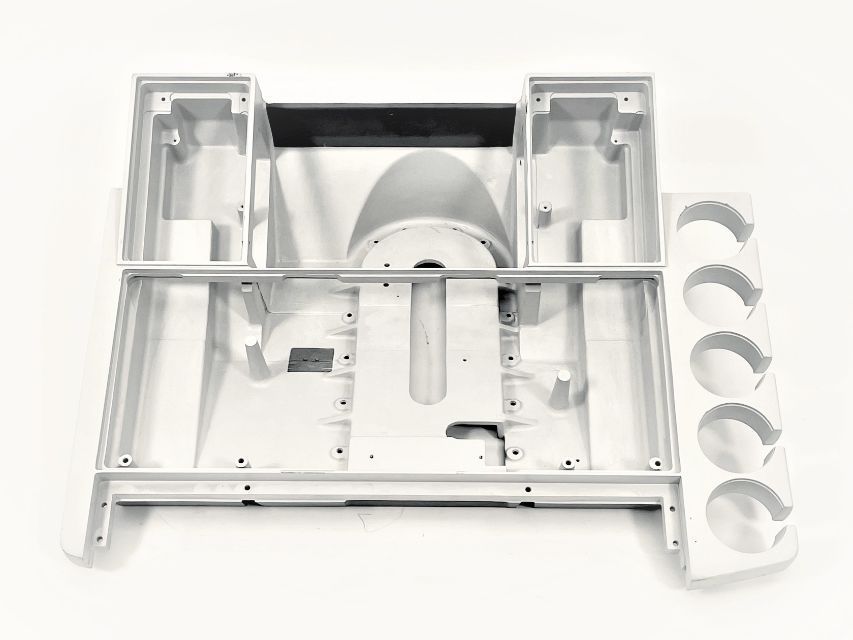

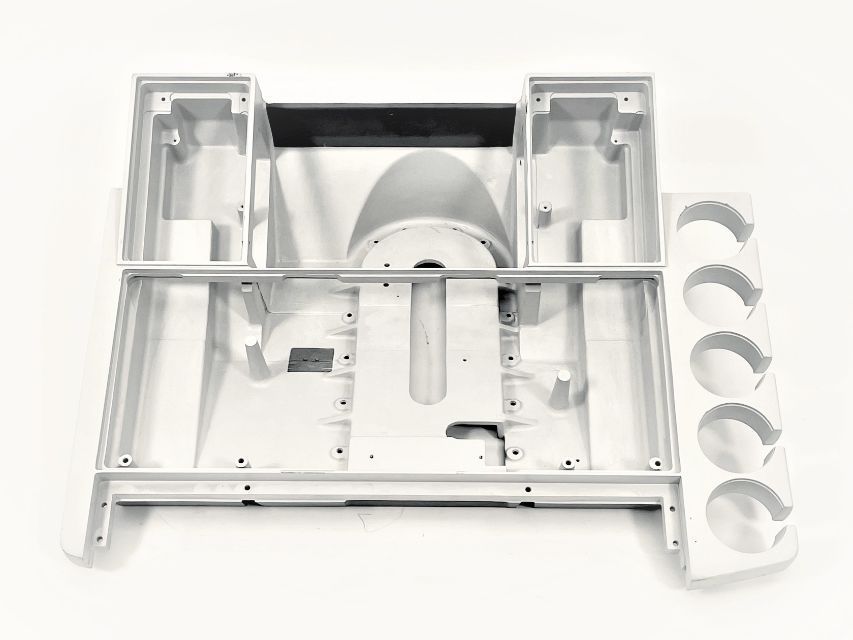

There are many advantages to designing with cast aluminum materials. They are versatile and cost effective and can go into production quickly. Complex parts can be cast at a significantly lower cost than machined hog outs or fabricated components. Multiple parts that would have to be machined separately and assembled can often be molded and cast as a single unit, increasing the structural integrity of the unit and reducing its cost. Even large parts that would otherwise be impossible to produce can be cast using aluminum alloys.

Aluminum castings have unique physical properties and performance characteristics not found in other materials. Cast aluminum components have high strength to weight ratio, excellent corrosion resistance, high impact resistance and are non-magnetic. They perform well at both high and low temperatures.

Contact us to explore the possibilities of aluminum casting project. Our engineers will support your project from first inquiry through every phase to complete manufacturing of your product. For more general information, check out our Quick Reference Guide.

Note: Each section contains information about specific subjects or terms as they apply to Pentz Cast Solutions. The Guide is as accurate as possible; however, all material is provided without warranty of any kind.

Call 1-425-788-6490 to contact a Pentz Cast Solutions Sales Engineer or Representative.