.png)

Japanese Mitsubishi Zero Tail Wheel Casting, 3D Printed Mold & Core

The Challenge:

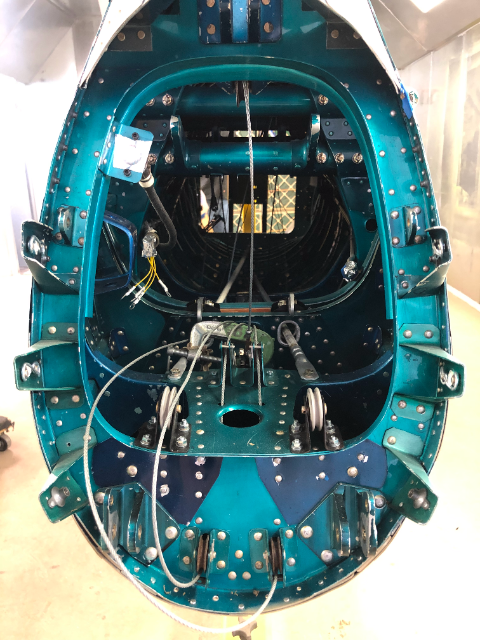

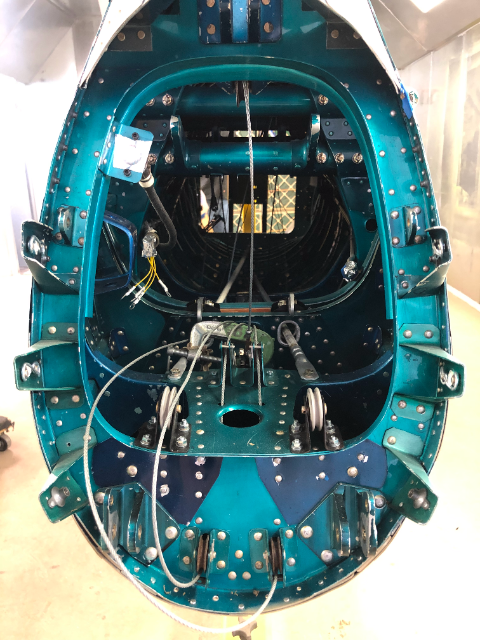

Create a fully functional aluminum casting Tail Wheel bracket from a severely corroded / eroded original part from the 1940s.

The Solution:

Create a 3D CAD model for the part. Create a 3D CAD model ror the mold to cast the part with casting rigging. Build a 3D Printed sand mold with cores. Finish, assemble, the mold & cores. Pour aluminum casting. Heat Treat, finish and CNC machine the casting.

.png)

The Results:

A fully functional structurally sound flying finished product to restore a Japanese Mitsubishi A6M “Zero” aircraft to flying condition after 70 years.

Contact Us

Our engineers have experience creating mission-critical components for virtually any industry, and we thrive on challenging projects and love to explore innovative cast solutions in collaboration with our customers to push beyond boundaries. We can create small castings, large castings, prototypes, 3D printed molds and additional components from most machinable materials.

Contact Us and we can discuss your next project or Request for Quote on our casting services online.