Innovation Engineering / Design & CAD Development

Casting Development from Prototyping to Production

Creating effective casting prototypes is imperative prior to rolling out high-volume production or manufacturing processes. Whether this is your first casting design or you have experience, Pentz can help you transform your design into high-quality casting at the lowest possible cost. Our engineers will work with you step by step to ensure the manufacturability of the design and develop processes capable of meeting your requirements. In many cases we are able to recommend design modifications that will reduce costs, enhance the functionality of a part, and improve quality.

Learn more about our casting development process below, Request a Quote on your next project or Contact Us online to get started creating castings for your requirements.

The Pentz Casting Development Process

Custom Casting Solutions Catered to Your Needs

Our expert engineers collaborate with customers on projects to simplify the complex casting developmental process. Together we can quickly identify best design configuration, casting process, alloy, and tooling approach, for cost savings and optimal manufacturing plan to yield exceptional results.

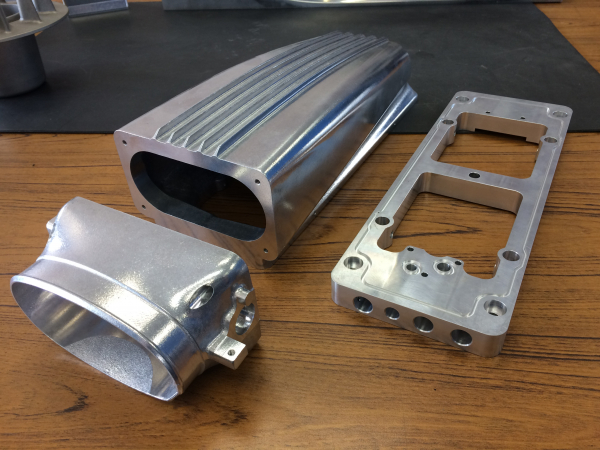

Casting Prototyping & Development

We identify the best process to build your parts and explore all options in engineering, CAD, prototyping, production casting tooling, production CNC machined parts and complete manufacturing. We can incorporate geometries, complex intricate coring, conversions from CNC machined billet and weld fabricated assembly into one casting to reduce costs.

Advanced CAD Capabilities

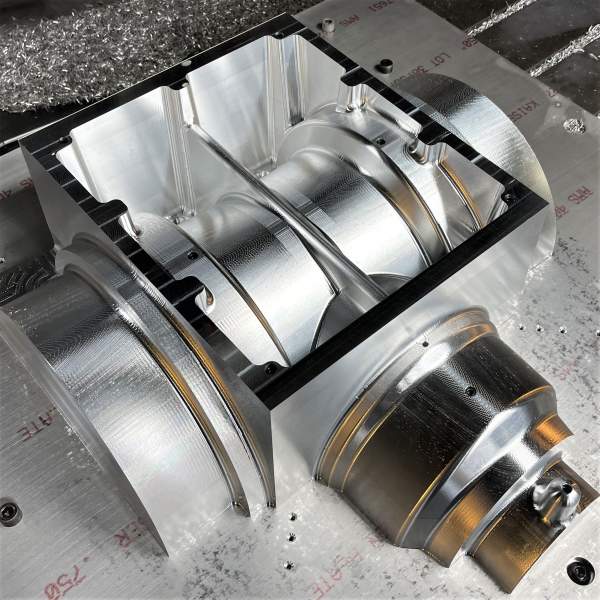

We reverse engineer parts utilizing Laser Scanning of external surfaces and or CT X-ray Scanning for interior negative spaces. Our engineers collect the data to create 3D CAD models of part geometry, create drawings and, documentation. Upon customer approval of 3D models and drawings, our engineers design casting tooling in CAD. The approved tooling is built by CNC machining casting tooling.

Why Choose Pentz for Casting Design & CAD Development

Our skilled engineers utilize industry expertise, higher-strength alloys and materials and the Pentz streamlined casting creation process to create castings lightweight castings with increased performance at lower costs to you. Our experience across multiple industries means we can identify the best casting process and best tooling approach with our extensive tooling solutions.

Pentz’s CAD software and CNC machining abilities allow us to identify great design features and incorporate tight tolerances and unique shapes into the casting geometry. These advantages give us the ability to explore several design options in CAD with minimal risk to cost and schedule. Because each casting process is unique, we look to create opportunities for product improvement quickly and efficiently.

CAD/CAM/CNC Software & Capabilities

Our CAD/CAM/CNC software allows us to design components with tight tolerances and complex geometries for CNC manufacturing. By utilizing tooling software, we can machine almost any casting with improved accuracy and shortened timelines. Our software offering includes:

- Cimatron Programming Software w 5th Axis

- Vericut Software

- Solidworks

- Sterolithography (STL)

- Rapid Casting Technology (ProMetal RCT™)

Additional Advantages of Pentz’s Casting Prototyping & Development Solutions

Many castings start as prototypes. Our company is geared toward assisting you in rapid prototype development. Using the latest in computer aided design (CAD), computer aided manufacturing (CAM) , sterolithography (STL) and Rapid Casting Technology (ProMetal RCT™), Pentz has the capability to create fully functional cast aluminum prototypes in a matter of days or even hours.

Additionally, Pentz’s ability to produce “real castings real fast” enhances the sales and marketing of new products more quickly and effectively than standard casting methods.

Casting Development for Multiple Industries

We have experience providing molds and components for a variety of applications and are always eager to create unique molds for low and high-volume production. Some frequent industries served include:

- Aerospace

- Medical / Robotics / Life Sciences

- Railroad / Positive Train Control electronic cases

- Defense / Military / Homeland Security

- Transportation / Automotive / Truck / Electric Vehicle

Casting Development Materials Used

While we specialize in aluminum castings, our unique CNC machining offers numerical controlled machining capabilities that enable us to form accurate, complex parts from a variety of materials. We’ve created castings in low to high volume production for plastic, hard wood and pattern pine. Our most popular selection of aluminum grades includes:

- 535 AlMag

- A356 alloy

- 357 alloy

- 206 alloy

- Alcoa 351 SuperaCast

- Alcoa A354 VersaCast

- CNC machined aluminum billet

- Plastic

- Hardwood

- Prototype Materials for quick tooling revisions

Casting Development Considerations Prior to Prototyping

There are several factors to consider prior to designing a casting configuration for your applications, such as:

- Quality

- Lead Time Constraints

- Economics/Costs

- Functional Requirements for Design

- Industry and Government Standards

- Part Size and Complexity

- Dimensional Tolerances

- Appearance

- Alloy Selection

- Tooling and Machining Allowances

- Inspection and Test Requirements

- Process Capability

Contact Pentz For Custom Cast Solutions

We thrive on challenging projects and love to explore creative innovative cast solutions in collaboration with our customers to push beyond boundaries. Request a Quote online or Contact Us and let us get started on your next project.