Applications For Industrial CNC Machined Castings & Components

As a leader in casting innovations since 9172, Pentz Cast Solutions has experience working with OEMs to create complex and mission-critical components for virtually every industry. Our skilled engineers understand the need to develop application-specific parts that meet stringent application requirements, and our ITAR-Registered prototyping and manufacturing processes ensure you get the highest quality castings available. We utilize a collaborative approach, impressive CAD software, CNC machining equipment and suite of in-house engineering and manufacturing capabilities to provide components in high volumes for any application.

Learn more about our castings applications below, Request a Quote on your next project or Contact Us online to get started creating castings for your requirements.

Applications & Frequent Casting Industries

Electrical/Electronic/Enclosures

Improve aesthetics, audio performance, and improve cost in your Electrical, Electronic equipment & Enclosures. We have experience working with specialized aluminum to create high elongation for large speakers and concert speakers. This involved converting a large, complex, aluminum sheet metal & tubing weldment assembly into two large castings

Safety/Construction

We can create small castings, large castings, prototypes, 3D printed molds and additional components from most machinable materials. This includes creating more efficient and safer components for construction equipment, including heavy equipment components. We have solved challenges for major manufacturers, including creating a diecasting assembly with steel inserts for OEMs such as Caterpillar.

Semi-conductor

Our skilled engineers have the know-how to create components for semi-conductors and semi-conductor production. We can utilize our Sinto Automated Molding System to create prototypes for approval while using real-time x-ray to inspect results. This includes creating Cast in SS Tubing. View example components by visiting our Semi-Conductor page.

Transportation/Automotive/Truck/Electric Vehicle

Our unique machining capabilities allow us to create components for most automotives, including vintage cars, electronic vehicles, motorcycles, engine components and transportation parts in high volumes. View our example case studies:

- Indian Motorcycle Engine

- Japanese Zero Tail Wheel Casting

- Crocker Reverse Engineering

- Studebaker Head

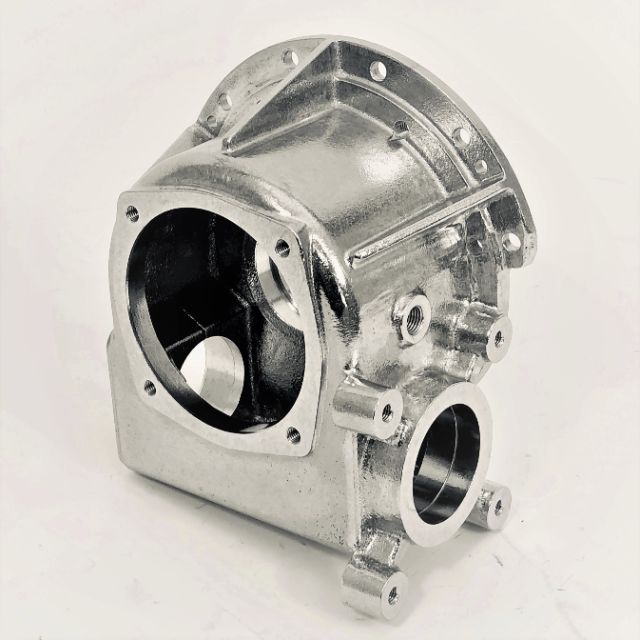

Engines/Gear Boxes/Pumps

We have experience creatingEngines, Gear Boxes and Pumps to form critical engine components. Examples of our work include:

- Aerospace Fuel Systems

- Defense Gear Boxes

- Gas Turbine Generators

- Missile Sile Emergency Evacuation Gear Boxes

- Nonmagnetic Diesel Heads & More

Railroad/Positive Train Control electronic cases

Pentz Cast Solutions’ engineers can create Railroad / Positive Train Control electronic cases from various materials. We have built rugged Positive Train Control electronic enclosures for as many as 25,000 locomotives in North America. We can utilize two horizontal CNC Haas EC 400 Pallet Pool and Haas EC 500 to build castings and CNC machined parts simultaneously, while navigating government regulations and schedules across multiple railroads.

We have also built as cast “O” ring grooves and faces to machining tolerances on drawings using precision aluminum sand casting capabilities.

Exercise Equipment

Popular Exercise Equipment components include CNC machined steel inserts for high volume production in Precor Exercise Equipment subject to high repeatability.

Precision Molding, Casting Development & CNC Machining Across Industries

We are always looking to expand our service offering by creating castings for new and unique applications. Additional industries include but are not limited to:

Precision Casting Molding, Machining & Tooling For Most Applications

In addition to our selection of 3 axis, 4 axis and 5 axis CNC machining equipment and CAD/CAD/CNC software, we are able to perform custom machining services for application-specific requirements. Our in-house CNC machining capabilities ensure each component is manufactured by a dedicated, skilled Pentz machinist. View our Prototyping Services Page for more information on our capabilities, materials used and the prototyping flow process. Additionally, our Case Studies provides insights and examples into our specific casting applications.

Contact Pentz For Application-Critical Castings

Contact a Pentz Expert and we can get started finding the right casting process to meet your requirements.